Prompt repair of a failed system often depends on the availability of spare parts at the maintenance location, whether it's a fixed or mobile maintenance facility. Spare parts forecasting, spare parts demand forecasting, and optimization predict the spare parts required to deal with system maintenance with an optimal logistics footprint efficiently. It involves considering both the predictable changes in hardware and the foreseeable changes in operating and support scenarios.

QVISE's Software Tool and Spare Parts Forecasting Technique for Spare Forecasting And Optimization (SFO)

QVISE has developed a software tool for Spare Forecasting And Optimization (SFO) that can help minimize downtime by ensuring spare parts are available when and where needed through spare parts forecasting techniques. Our tool is the first and only for developing optimum spare scales to meet fleet spare parts inventory availability targets where operational usage or fleet disposition changes over time, though fleet expansion is also considered. It can accommodate re-basing, re-role or run-down, equipment design changes due to obsolescence, modifications, upgrades, or reliability improvement programs, and support arrangement changes over time as maintenance, repair policies, contractors, performance, and prices evolve.

QVISE's Expertise in Spare Parts Management

At QVISE, we have a wealth of knowledge in spare parts management, including forecasting inventory, optimizing our logistics footprint, providing spare parts service, and parts inventory management. Our team has assisted many clients in streamlining their spare parts management procedures to decrease downtime and increase productivity through the availability of spares. We are well-versed in spare parts management, and parts inventory management and have access to the most up-to-date equipment and methods to satisfy the demands of our customers.

Benefits of QVISE's Spare Forecasting And Optimization (SFO) Tool

QVISE's Spare Forecasting And Optimization (SFO) tool offers numerous benefits for spare parts management, including:

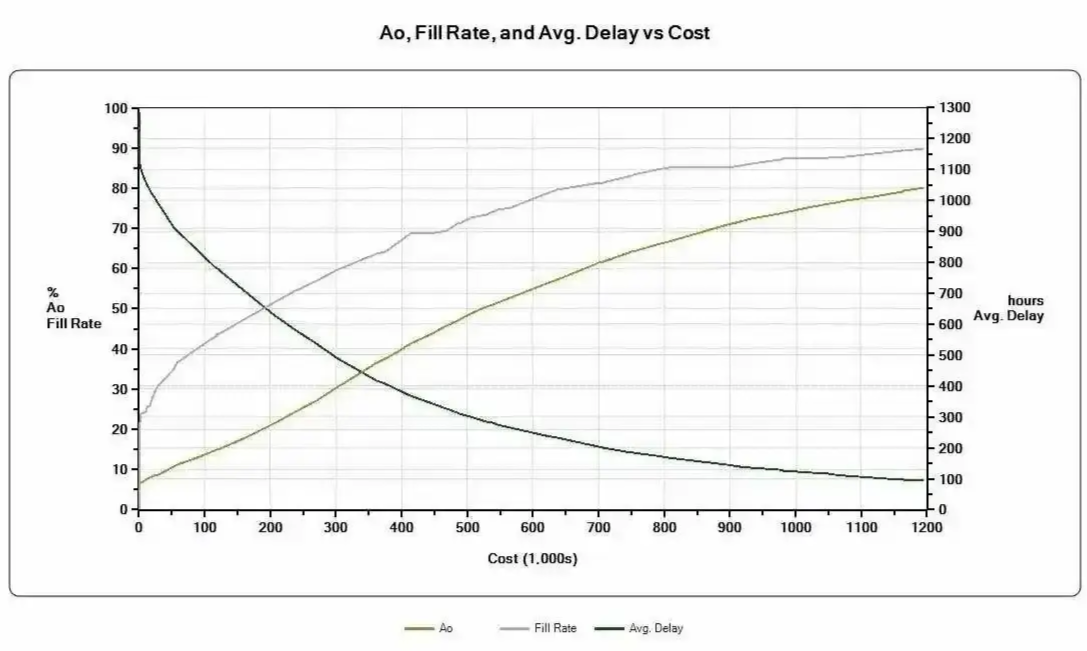

- Predicting spare parts requirements for efficient system maintenance

- Minimizing downtime by ensuring spare parts availability

- Optimizing logistics footprint by predicting the locations where spare parts will be required

- Considering changes in hardware and operating and support scenarios over time

- Developing optimum spares scales to meet assets Operational Availability (Ao) targets

Our Achievements in Spare Forecasting and Minimization

At QVISE, we have extensive experience in spare parts management, including forecasting inventory, logistics footprint optimization, and spare parts service. Our team has helped numerous clients optimize their spare parts management processes, reducing downtime and improving efficiency. Our Spare Forecasting And Optimization (SFO) tool is just one of the many solutions we offer to help clients achieve their goals in spare parts management.