QVISE’s IPS solutions offer a comprehensive approach to optimizing maintenance planning and management, integrating all aspects of maintenance management, including planning, scheduling, and execution, into a single system. This ensures efficient and timely maintenance of support items, minimizing downtime and maximizing productivity. We provide a comprehensive approach to manpower management for product support. The solution enables the efficient management of manpower resources, including allocation, scheduling, and utilization, ensuring that the right people are available at the right time to provide support.

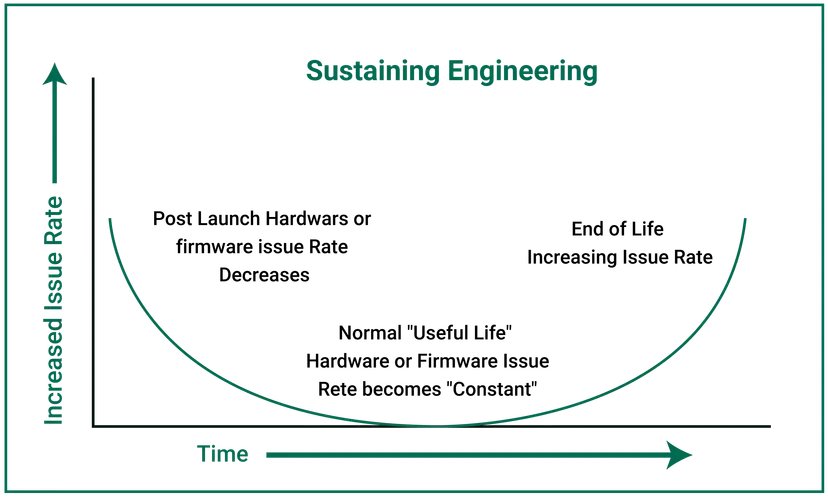

Sustaining Engineering activities are heavily influenced before system deployment by the design interface activities, which focus on optimizing Availability and Reliability at reduced Life Cycle Costs. In today’s world, the biggest challenges are – fast-paced technological changes, process changes, and skill-based changes, which need continuous improvement, upgradation, prevention, or simply a refresh of technical foundations. Our experts do consider these aspects of Sustaining Engineering and propose Obsolescence Management (OM)(also referred to as DMSMS: Diminishing Manufacturer Sources & Material Shortages) through upgradation or replacements to have the lowest possible logistic footprints with desired Operational Availability (Ao).

QIVSE is experienced in providing Supply Support services based on the FLSIP (Fleet Logistics Support Improvement Program) models for consolidating onboard allowance for 90 days of continuous operation at sea as well as COSMAL (Co-ordinated Shore-based Material Allowance List) for depot allowance for 3 years. Accordingly, low and high levels of stores are also established as per the platform’s usage. Furthermore, we provide a List of all recommended workshop machinery, equipment, tools, and test benches to be purchased and installed at the client’s site to support Depot Level maintenance. We are also working on Readiness Based Sparing (RBS, US model) / Marginal Analyses (UK model) to further optimize the logistic footprint. QVISE makes sure that the customer’s objective is completed with the specified model, whether customer specific or a predefined model.

Our engineers define the repair and upkeep tasks, schedule, and resources required to care for and sustain equipment/systems, with the focus being to define the actions and support necessary to achieve the system’s Operational Availability (Ao) (AO)objective. They establish maintenance concepts and requirements for the life of the system, hardware, and software, including:

Our experts identify, plan, resource, and define PHS&T (Packaging / Preservation, Handling, Storage & Transportation) requirements to maximize the availability and usability of the material to include support items whenever they are needed for training or mission success. Our team also considers the combination of resources, processes, procedures, design, and methods to ensure that all systems, equipment, and support items are preserved, packaged, handled, and transported properly, including environmental considerations, and equipment preservation for the short and long term storage and transportability. Some items require special, environmentally controlled, shock-isolated containers for transportation to and from repair and storage facilities via any mode of transportation (land, rail, air, and sea).

Our technical manual authors acquire, study & record information of a scientific or technical nature, regardless of form or character (such as equipment technical manuals and engineering drawings), engineering data, specifications, standards, and Data Item Descriptions (DID). They then combine all information in the form of Technical Manuals (TMs), including Interactive Electronic Technical Manuals (IETMs) and engineering drawings, being the most expensive and the most important data made for the support, operation, and maintenance of a system. IETMs also provide integrated training and diagnostic fault isolation procedures. A data management system developed by QVISE the LCSP – establishes within the system provisions that can allow every activity involved with the program to cost-effectively create, store, access, manipulate, and exchange digital data. Technical data includes, at minimum, the data management needs of the SE process, modeling and simulation activities, test and evaluation strategy, support strategy, and other periodic reporting requirements. It also includes as-maintained (in addition to the as-built) bills of material and system configuration by individual system identification code or “Part Number.

QVISE analysts focus on identifying, planning, resourcing, and implementing management actions in the acquisition of Support Equipment (be it mobile or fixed but is not limited to ground handling and maintenance equipment, trucks, air conditioners, generators, tools, metrology and calibration equipment, and manual and automatic test equipment) required to sustain the operation and maintenance of the system to ensure that the system is available to the platform when it is needed at the lowest Total Ownership Cost (TOC) with the defined Operational Availability (Ao) requirement as outlined by the client. This is achieved by defining the PMs (Preventive maintenance) efficiently and effectively during the acquisition of systems, leading to a decrease in the proliferation of support equipment into the inventory by minimizing the development of new support equipment and giving more attention to the use of existing Government or client’s equipment.

QVISE’s team of experts identifies, develops and list down Training Aids, Devices, Simulators, and Simulations (TADSS) to be acquired by the client to train military and civilian personnel to maximize the effectiveness of the manpower and personnel to fight, operate, and sustain equipment at the lower Total Ownership Cost (TOC). This includes New Equipment Training (NET), institutional, sustainment training, and Displaced Equipment Training (DET) for the individual, crew, unit, collective, and maintenance through initial, formal, informal, On-the-Job Training (OJT), and sustainment proficiency training. Significant efforts are focused on NET, which in conjunction with the overall training strategy, is validated during system evaluation and test at the individual-, crew-, and unit levels.

Our manpower analysts determine the number of Personnel required, authorized, and available to operate, maintain, support, and provide training for the system. Manpower requirements are based on the range of operations during peacetime, low-intensity conflict, and wartime. It represents the number of personnel or positions required to perform a specific task. Manpower is typically the highest cost driver in the development and sustainment of the programs/platforms and can account for 67-70% of the program budget. When Manpower Planning is engaged along with Human Systems Integration, Our Program Managers have the tools to effectively manage systems and to ensure that the human elements of the system are included in the pros, cons, and risks of using a program.

Our experts visit the client’s Facilities to evaluate the Facility & its Infrastructure used for carrying out maintenance activities, especially Depot Level Maintenances, to lay down the requirement for either a new mobile / fixed maintenance facility or an upgradation for an existing one. Based on these evaluations if the facility requires upgradation, the team recommends augmenting the facility in the form of the erection of new support equipment/test benches, jigs, etc. so that the equipment/machinery can be easily maintained by the client’s skilled manpower. This also includes training of support Facility’s skilled staff to acquire training for efficiently maintaining the equipment.

Our IT team of seasoned specialists and engineers can identify computer hardware & software requirements onboard ship and ashore to manage administrative and support (maintenance planning, execution & recording, and Logistics requirement) functions. They are proficient in installing hardware and software at the client’s site and integrating wired and wireless networks (LAN, WAN, MAN) efficiently and effectively.

With extensive experience in the domain of IPS, QVISE has provided customized solutions, facilities, and infrastructure to various industries, including aerospace, defense, and transportation. The company’s team of experts possesses in-depth knowledge and understanding of the challenges faced in product support, offering tailored solutions to meet each client’s unique needs. Trust QVISE for efficient and reliable product support.

Based on the evaluation, the QVISE team recommends augmenting the facility with new support equipment, test benches, jigs, etc., to enable the client’s skilled manpower to maintain the equipment/machinery efficiently. This also includes training the facility’s skilled staff to efficiently maintain the equipment efficiently, ensuring optimal performance and longevity.

Our IT team is proficient in installing hardware and software at the client’s site, ensuring seamless integration with existing systems. Trust us to efficiently integrate wired and wireless networks, including LAN, WAN, and MAN.

QVISE’s team of experts specializes in the identification, planning, and execution of Packaging, Handling, Storage, and Transportation (PHS&T) requirements for maximum availability and usability of materials, including support items, needed for mission success and training. Our team considers a comprehensive approach to PHS&T, combining resources, processes, procedures, design, and methods to ensure proper preservation, packaging, handling, and transportation of all systems, equipment, and support items. We also consider environmental considerations, including equipment preservation for short- and long-term storage and transportability.

Before system deployment, sustaining engineering activities heavily focus on design interface activities to optimize availability and reliability at a reduced life cycle cost. In today’s rapidly changing world, technological, process, and skill-based changes require continuous improvement, upgrading, prevention, or simply a refresh of technical foundations. We consider these aspects of sustaining engineering and propose Obsolescence Management (OM) through upgrades or replacements to minimize logistic footprints while ensuring desired Operational Availability (Ao). To address the challenges posed by diminishing manufacturing sources and material shortages (DMSMS), our experts propose Obsolescence Management (OM) as a part of their sustaining engineering activities. This involves upgrading or replacing obsolete equipment and systems to minimize the logistical footprint while ensuring the desired Operational Availability (Ao).

QVISE specializes in Technical Data Management, which includes acquiring, recording, and managing technical information, such as engineering data, specifications, standards, and Data Item Descriptions (DID), required for the support, operation, and maintenance of a system. The company’s technical manual authors combine this information to produce Technical Manuals (TMs), including Interactive Electronic Technical Manuals (IETMs) and engineering drawings, which provide integrated training and diagnostic fault isolation procedures.

QVISE has developed a data management system, the LCSP, which enables all activities involved in a program to cost-effectively create, store, access, manipulate, and exchange digital data. Technical data managed through the LCSP includes the needs of the SE process, modeling and simulation activities, maintenance planning, test and evaluation strategy, support strategy, and periodic reporting requirements. Additionally, it includes as-maintained bills of material and system configurations by individual system identification code or ‘Part Number.’

With our IPS services, we provide a wide variety of solutions crafted to satisfy the particular requirements of your business. We address all aspects of product support, from initial planning and design to deployment and continuous maintenance. We take care of your demands for product support while we take care of your main business activities thanks to our comprehensive strategy, which guarantees seamless integration of support processes. We can comprehend the particular issues you might be facing and offer practical answers because of our in-depth industry knowledge and technological proficiency.

With a team of experts possessing in-depth knowledge and understanding of the challenges in product support, QVISE has provided customized solutions to various industries, including aerospace, defense, and transportation, gaining extensive experience in the domain of IPS. To learn more, Click here to view our brochure.

To learn more, Click here to view our brochure.