QVISE is a leading provider of Integrated Product Support (IPS) solutions that aim to enhance product support processes and improve customer satisfaction. With a focus on support items, sustainment, maintenance management, and manpower management, QVISE's IPS solution offers a comprehensive and streamlined approach to product support.

EFFICIENT MAINTENANCE AND MANPOWER MANAGEMENT

QVISE's IPS solutions offer a comprehensive approach to optimizing maintenance planning and management, integrating all aspects of maintenance management, including planning, scheduling, and execution, into a single system. This ensures efficient and timely maintenance of support items, minimizing downtime and maximizing productivity. We provide a comprehensive approach to manpower management for product support. The solution enables the efficient management of manpower resources, including allocation, scheduling, and utilization, ensuring that the right people are available at the right time to provide support.

TRUSTED SOLUTIONS FOR PRODUCT SUPPORT

With extensive experience in the domain of IPS, QVISE has provided customized solutions, facilities, and infrastructure to various industries, including aerospace, defense, and transportation. The company's team of experts possesses in-depth knowledge and understanding of the challenges faced in product support, offering tailored solutions to meet each client's unique needs. Trust QVISE for efficient and reliable product support.

AUGMENTING FACILITIES FOR OPTIMAL MAINTENANCE

Based on the evaluation, the QVISE team recommends augmenting the facility with new support equipment, test benches, jigs, etc., to enable the client's skilled manpower to maintain the equipment/ machinery efficiently. This also includes training the facility's skilled staff to efficiently maintain the equipment efficiently, ensuring optimal performance and longevity.

INSTALLATION AND INTEGRATION OF HARDWARE AND SOFTWARE

Our IT team is proficient in installing hardware and software at the client's site, ensuring seamless integration with existing systems. Trust us to efficiently integrate wired and wireless networks, including LAN, WAN, and MAN.

COMPREHENSIVE APPROACH TO PACKAGING, STORAGE, HANDLING AND TRANSPORTATION (PHS&T)

QVISE's team of experts specializes in the identification, planning, and execution of Packaging, Handling, Storage, and Transportation (PHS&T) requirements for maximum availability and usability of materials, including support items, needed for mission success and training.

Our team considers a comprehensive approach to PHS&T, combining resources, processes, procedures, design, and methods to ensure proper preservation, packaging, handling, and transportation of all systems, equipment, and support items. We also consider environmental considerations, including equipment preservation for short- and long-term storage and transportability.

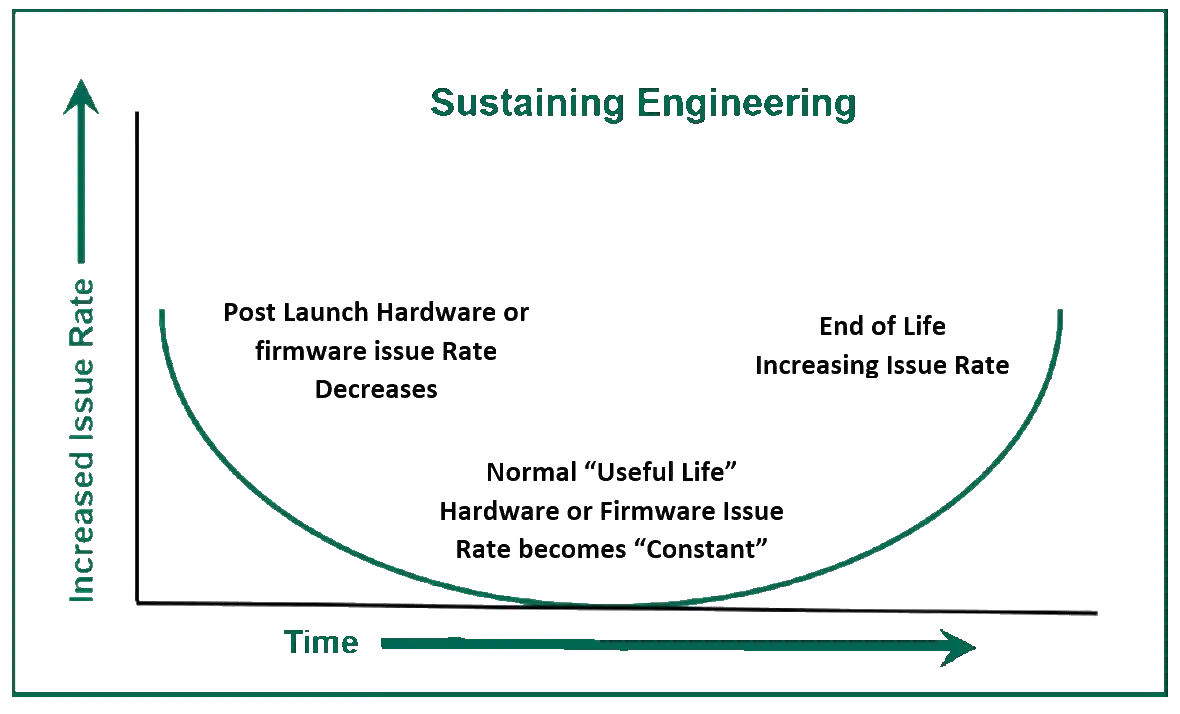

Obsolescence Management (OM) FOR MAXIMUM EFFICIENCY

Before system deployment, sustaining engineering activities heavily focus on design interface activities to optimize availability and reliability at a reduced life cycle cost. In today's rapidly changing world, technological, process, and skill-based changes require continuous improvement, upgrading, prevention, or simply a refresh of technical foundations. We consider these aspects of sustaining engineering and propose Obsolescence Management (OM) through upgrades or replacements to minimize logistic footprints while ensuring desired Operational Availability (Ao) . To address the challenges posed by diminishing manufacturing sources and material shortages Diminishing Manufacturing Sources and Material Shortages (DMSMS), our experts propose Obsolescence Management (OM) as a part of their sustaining engineering activities. This involves upgrading or replacing obsolete equipment and systems to minimize the logistical footprint while ensuring the desired Operational Availability (Ao) .

TECHNICAL DATA MANAGEMENT

QVISE specializes in Technical Data Management, which includes acquiring, recording, and managing technical information, such as engineering data, specifications, standards, and Data Item Descriptions (DID), required for the support, operation, and maintenance of a system. The company's technical manual authors combine this information to produce Technical Manuals (TMs), including Interactive Electronic Technical Manuals (IETMs) and engineering drawings, which provide integrated training and diagnostic fault isolation procedures.

LCSP DATA MANAGEMENT SYSTEM

QVISE has developed a data management system, the LCSP, which enables all activities involved in a program to cost-effectively create, store, access, manipulate, and exchange digital data. Technical data managed through the LCSP includes the needs of the SE process, modeling and simulation activities, maintenance planning, test and evaluation strategy, support strategy, and periodic reporting requirements. Additionally, it includes as-maintained bills of material and system configurations by individual system identification code or "Part Number."

TRUSTED SOLUTIONS FOR PRODUCT SUPPORT

With our IPS services, we provide a wide variety of solutions crafted to satisfy the particular requirements of your business. We address all aspects of product support, from initial planning and design to deployment and continuous maintenance. We take care of your demands for product support while we take care of your main business activities thanks to our comprehensive strategy, which guarantees seamless integration of support processes. We can comprehend the particular issues you might be facing and offer practical answers because of our in-depth industry knowledge and technological proficiency.

ACCOMPLISHMENTS

With a team of experts possessing in-depth knowledge and understanding of the challenges in product support, QVISE has provided customized solutions to various industries, including aerospace, defense, and transportation, gaining extensive experience in the domain of IPS.

, Supply Support, logistics support, ground support, ground support equipment, integrated logistic support, integrated logistics support.webp)

.webp)

.webp)

, Support Equipment, ground support equipment, integrated logistic support, integrated logistics support, logistics support, ground support.webp)